Photo: DLR

Within the IEA Solar Heating and Cooling Programme, preparations have been made to establish a new international research platform focusing on nearly market-ready technology and processes for industrial solar heat (SHIP) with temperatures of up to about 400 °C. “Our aim is to raise the profile of solar heat, which has been a reliable and affordable source of energy for industry,” said Andreas Häberle (photo right), Director of the Swiss-based SPF – Institute for Solar Technology, who coordinates work in the definition stage. In March, a number of SHIP experts met in Cologne, Germany, to discuss what the research agenda of the platform should look like.

The project, titled Solar Energy for Process Heat Systems, will be implemented in close cooperation with members of the Solar Power and Chemical Energy Systems programme, or SolarPaces for short. Like IEA SHC, SolarPaces is a Technology Collaboration Programme (TCP) created by the IEA but with the aim to develop and market concentrating solar power (CSP) technology and electricity generation methods. Klaus Hennecke (photo left), Director of the Line Focus Systems Department at the German Aerospace Centre, or DLR, will co-chair the new platform and report its findings to SolarPaces, whereas Andreas Häberle will coordinate work among SHC researchers. The project could be launched as soon as it is approved by both TCPs and run for four years starting in early 2020.

The meeting of SHIP experts in Cologne again proved that the two research fields, solar thermal and CSP, complement each other well: CSP technology suppliers often develop systems that inject steam directly into pipelines operated by their customers, which means they usually design relatively large units with 500 kWth or more and put a block of pumps between the solar field and the steam network. Traditionally, solar heating and cooling researchers rather look at engineering solutions on a case-by-case basis to make the temperature requirement of each system match production processes.

Fruitful cooperation across disciplines

To both chairs, the contribution of SHIP technology suppliers is an important objective. To introduce the new research platform to a wide range of solar industry stakeholders, Häberle and Hennecke are planning to offer workshops in several parts of the world in the second half of this year. Two suitable occasions are the SolarPaces Conference, which will be held in early October in South Korea, and the International Conference on Solar Heating and Cooling for Buildings and Industry (SHC), which will be hosted in Chile in early November. They have also scheduled another research agenda meeting for 10 September at the SPF in Rapperswil, Switzerland. It will be open to both companies and researchers working in the field. To receive more information, please send an email to Andreas Häberle (contact details can be found at the end of this article).

Greener hybrid solutions

As described below, industry stakeholders discussed several issues at the first road map workshop in Cologne.

Standardised, modular hybrid solutions with high solar fractions

Earlier research findings have shown that SHIP technologies usually achieve a solar fraction of about 10 % to 20 % owing to space restrictions or greater heat demand in winter, when solar irradiation is lower. Manufacturing businesses, however, have been asking for technical solutions that mainly use renewables to meet the goals set out in the Paris climate agreement. “To achieve high proportions of renewable heat at factories, we are planning to create hydraulic diagrams as a frame of reference for several types of hybrid solutions combining solar systems with biomass boilers or heat pumps,” said Bastian Schmitt, who heads the working group on process heat at the University of Kassel and who is in charge of the Integrated Energy Systems unit within the new SHIP research network. The design of these solutions will depend on, for example, local climate conditions, usable roof space, load profiles and the amount of surplus heat available. Afterwards, the SHIP experts will identify standardised, modular components for the most common integration concepts.

Testing simulation tools

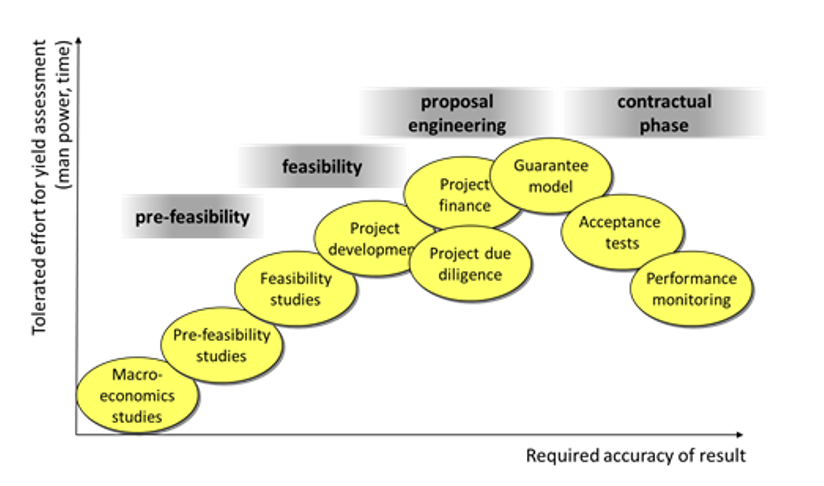

To optimise planning and sizing, it is crucial to have the right tools handy to simulate the operation of SHIP systems. Hence, the members of the Process Heat working group will test those available on the market, as well as their main features, identify their shortcomings, and make clear when to use them during planning and implementation (see the chart above). “We will base our analysis of the tools on the work done in IEA SHC research programmes 33 and 49,” said José Miguel Cardemil, Lecturer at the University of Chile, who will be in charge of this part of the work.

New business models and cost analysis

Häberle said the SHIP research platform was open to all stakeholders, whether they work in research, planning or solar collector manufacturing. “We will succeed if we can draw on the expertise available in several solar process heat markets throughout the world and develop a market-orientated dissemination strategy based on existing and new knowledge.”

If you like to know more about the upcoming SHIP research agenda workshops, you can send an email to Andreas.Haeberle@spf.ch or Klaus.Hennecke@dlr.de.

Organisations mentioned in this article: